TENSOLOGY Technicians provide in-situ cleaning and lubrication of wire ropes.

Wire ropes consist of hundreds of individual steel wires which move against each other each time the rope is loaded or bent. When wire ropes are made, a special lubricant is added during each stage of manufacture to reduce the inter-wire friction and hence reduce internal wear during service. Over time, the amount of manufacturing lubricant is reduced or removed and as a consequence, the rate of wear inside the rope increases. In some applications such as offshore lifting or port cranes, the local environment can also cause deterioration of the rope by corroding the wires. For these ropes, the applied lubrication also acts as a barrier to prevent both external and internal corrosion. As the amount of original manufacturing lubricant is reduced or removed over time, voids appear allowing moisture to enter the rope and become trapped inside. This moisture causes internal corrosion and will rapidly deteriorate the rope.

In order to prolong the safe working life, new lubricant should be applied to both the INSIDE and outside of the rope to reinstate the "as-built" levels of protection.

Tests have verified that the lifetime of a wire rope can be more than DOUBLED if the rope is periodically lubricated using the correct product and application technique. In order to internally lubricate a rope, either a low viscosity penetrating oil is sprayed or brushed onto the surface or a higher viscosity grease is pumped into the rope at high pressure to expel any moisture and to fill all the voids. TENSOLOGY Technicians use proven pressure lubrication equipment and approved lubricants to carry out site re-lubrication of all types of rope.

Tensology promote the use of Environmentally Acceptable Lubricants (EALS) during manufacture and throughout the service life of wire ropes. The Tensology range of EAL wire rope lubricants are compatible with existing manufacturing lubricants and provide the same level of performance. Our wire rope lubricants do not contain solvents which can "wash-out" existing lubricant.

Lubrication can be carried out in conjunction with Magnetic Rope Testing (MRT). TENSOLOGY technicians can carry out an MRT test and simultaneously lubricate the rope. Providing the rope is deemed safe following the test and subsequent assessment, it can be recertified and put back into service.

Lubrication can increase the lifetime of a wire rope by over 200%.

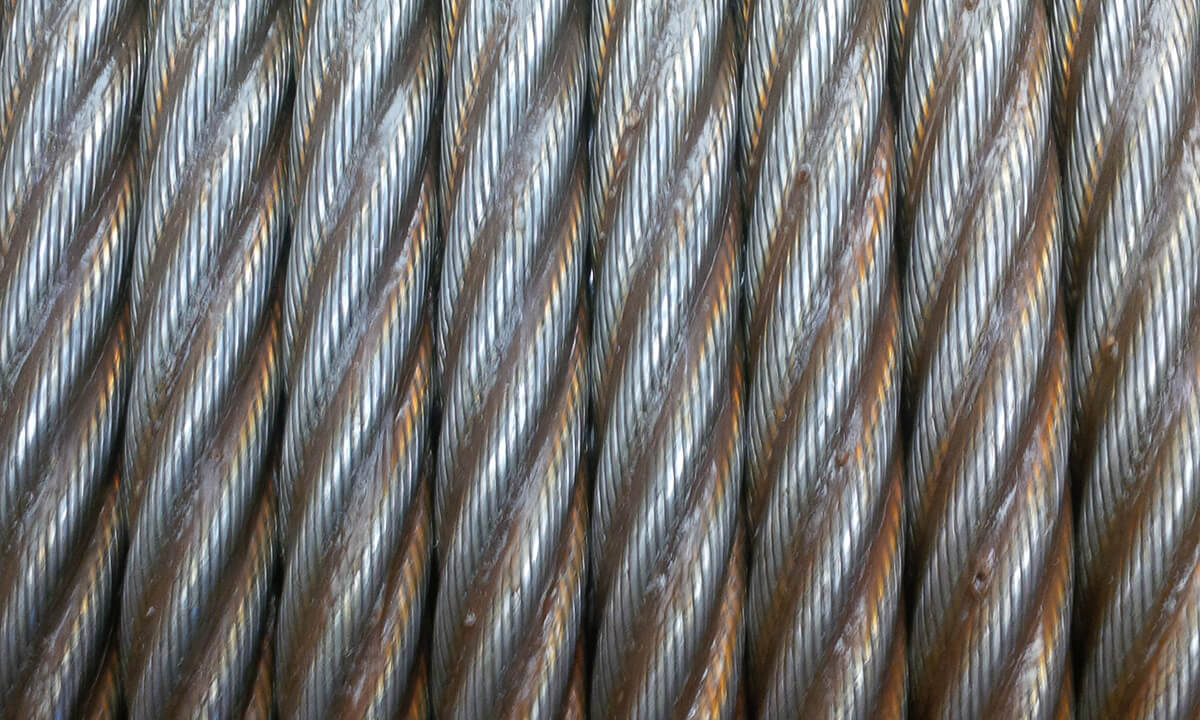

Well lubricated wire rope.

Well lubricated wire rope.